Polypropylene (PP) compounds

Used in car interiors, motorcycles, household appliances, and furniture, offering properties like elasticity, anti-deformation, electrical insulation, and high transparency.

Home›Engineering plastic compounds

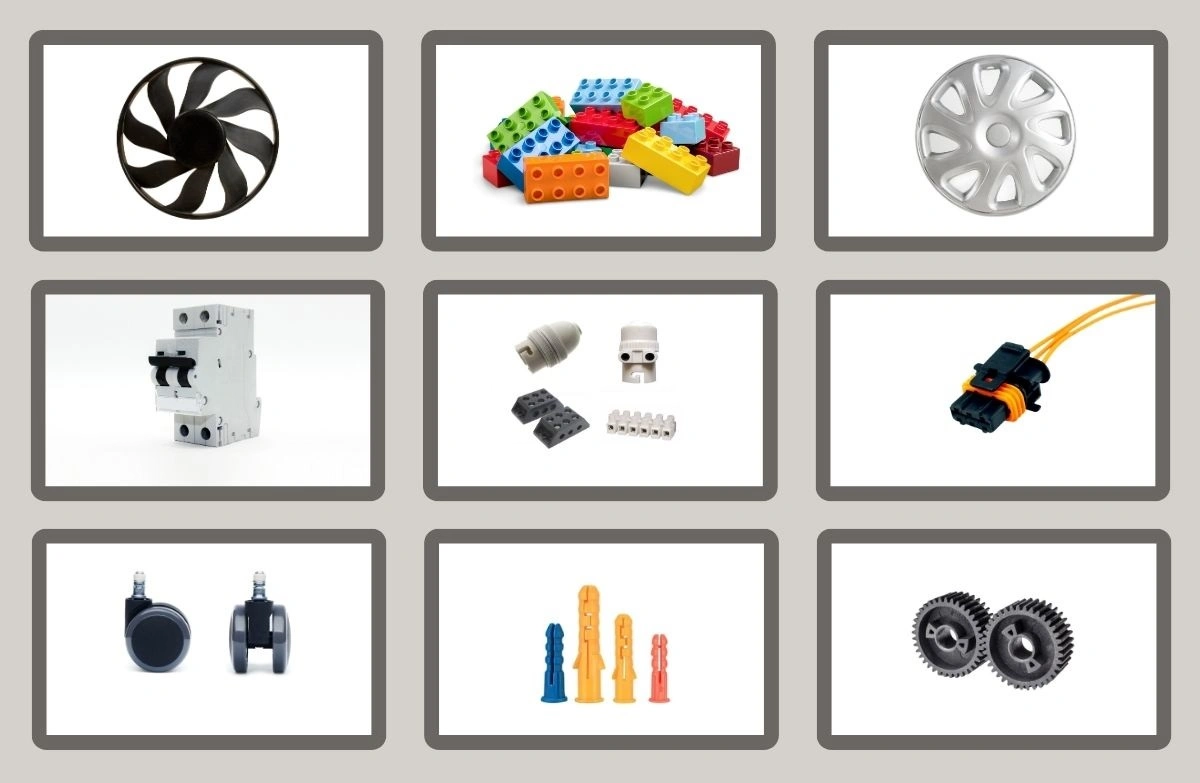

Engineering plastic compounds are a category of advanced plastic materials specifically designed and formulated to possess superior mechanical, thermal, electrical, and chemical properties compared to standard or commodity plastics. These compounds are created by combining primary plastic resins (like ABS, PP, PC, PA6, PA66) with reinforcing agents (such as glass fibers/beads, conductive carbon, flame retardants, talcum powder, or BaSO4 salts) and appropriate additives.

This specialized formulation allows engineering plastic compounds to be tailored to meet the specific technical requirements of a wide range of end products, making them suitable for demanding applications across various industries.

Engineering plastic compounds exhibit higher tensile strength, stiffness, and impact resistance than standard plastics, enabling them to withstand heavy loads and harsh operating conditions.

Many engineering plastics have higher melting points and better thermal stability, allowing them to operate effectively in environments with elevated temperatures, unlike their standard counterparts.

They offer improved resistance to a broad spectrum of chemicals, solvents, and acids, making them suitable for applications in corrosive environments.

Engineering plastics offer a unique combination of strength and lightweight characteristics, making them an ideal choice for applications where weight reduction is crucial (e.g., automotive and aerospace industries).

The versatility of these materials allows for easy molding into complex shapes, enabling intricate product designs and streamlined manufacturing processes.

Certain engineering plastics possess excellent noise and vibration damping capabilities, contributing to improved comfort and durability in applications like automotive interiors and machinery components.

Many varieties offer excellent electrical insulation, crucial for electronic components and wiring applications.

While the initial cost of engineering plastics may be higher than traditional plastics, their long-term cost-effectiveness is often superior due to their extended product lifespans, reduced maintenance, and potential for lighter designs (leading to energy savings in transportation, for example).

Engineering plastic compounds can be precisely formulated to achieve specific properties and performance characteristics required for a particular end product, simplifying manufacturing processes and potentially reducing costs associated with managing multiple raw materials.

Used in car interiors, motorcycles, household appliances, and furniture, offering properties like elasticity, anti-deformation, electrical insulation, and high transparency.

Widely used in the electrical and electronic industries, automotive parts (bumpers, dashboards), and toys due to their rigidity, impact resistance, and electrical insulation.

Applied in manufacturing computer components, office gears, household electrical components, and camera components, known for surface hardness, impact resistance, and anti-static properties.

Used in the production of gears, bearings, household electrical components, office equipment, and automotive parts like carburetors and fuel tank caps, known for strength, resistance to abrasion, dimensional stability, and wear resistance.

Utilized in car and motorcycle parts, radiator fans, and household electrical appliances, known for fire resistance and high rigidity.

Commonly used in mechanical parts such as bearings, nuts, plastic joints, and other components in water pumps, drills, and automotive assemblies, known for high hardness, good wear resistance, and stable dimensions.

Made from natural materials, offering environmentally friendly alternatives for disposable products like cutlery, cups, and packaging materials.

In conclusion, engineering plastic compounds are a crucial and growing segment of the plastics industry. Their ability to deliver enhanced properties and tailor-made solutions for diverse applications makes them indispensable in modern manufacturing and design. They enable innovation, improve product performance, reduce costs, and offer more sustainable alternatives to traditional materials across a wide range of industries, including automotive, electronics, healthcare, and construction.

Contact Us