Home›Products›Additive Masterbatches›Colour Masterbatches For Engineering Polymers

Colour masterbatches designed for polyolefin applications generally face shortcomings when being used in demanding engineering polymer based applications.

Incompatibility between the base resin being used in the end process compared to that in the masterbatches

Degradation of the masterbatch carrier resin due to higher processing temperatures in the end application

Colourants may not be able to withstand processing temperatures and exhibit other fastness properties

Any or all of the above could result in degradation in mechanical properties of the final product

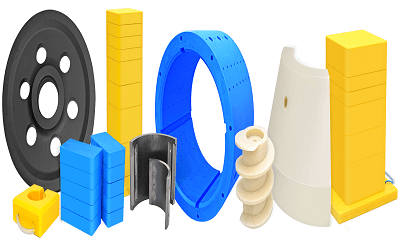

To overcome these problems Kandui offers Colour masterbatches that are custom made for engineering polymers such as Styrenics, PET, PBT, PC, SAN, ABS & Nylon.

To overcome these problems, engineering polymer color masterbatches are custom-developed to suit polymers with higher heat resistance and different polarity characteristics.

These engineering polymer masterbatches are specifically formulated to withstand high processing temperatures without compromising on dispersion, gloss, or mechanical properties. Whether it’s ABS, PC, Nylon, or PBT, using the right masterbatch for engineering polymers ensures consistent performance and colour matching across applications like automotive components, electrical housings, or high-end consumer goods.

Kandui offers engineering polymer color masterbatch solutions tailored for materials like Styrenics, PET, PBT, PC, SAN, ABS & Nylon. Each batch is created with precision to handle thermal load, prevent streaking, and retain performance integrity.

Also, as a leading color masterbatch manufacturer in India, we ensure all engineering polymer blends meet fastness, opacity, and safety standards.

We welcome you to please speak to our Marketing representatives for your specific requirements. We will be more than happy to cater to your needs.

There are primarily three types of masterbatches:

Contact Us