Home›Products›Additive Masterbatches›Polymer Processing Aid Masterbatches

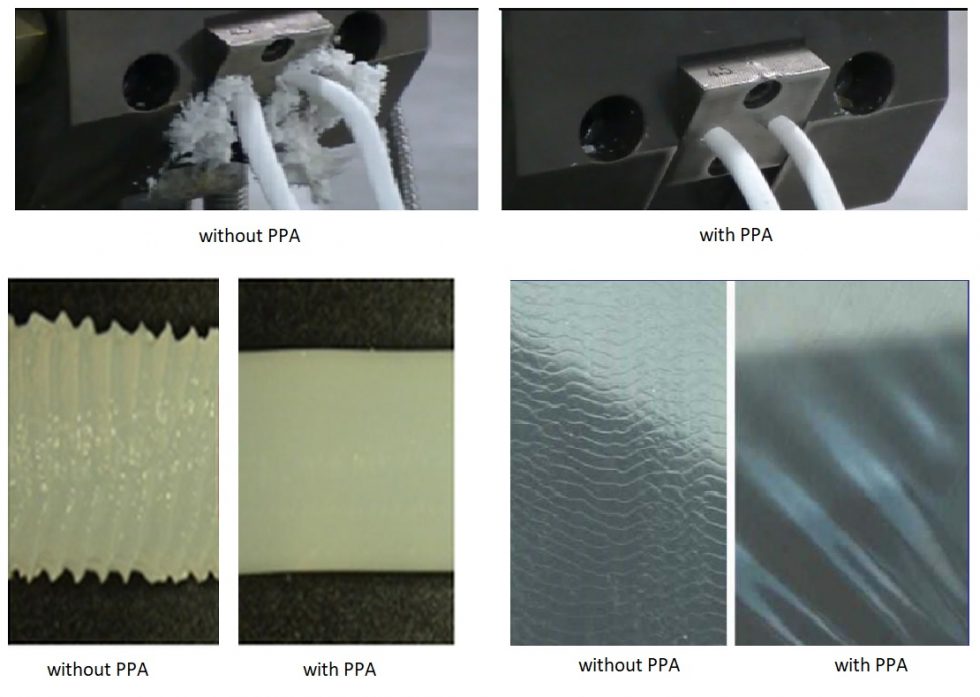

Polymer Processing Aid Masterbatches also known as PPA reduces the die build-up in most of the processes and eliminates melt fracture in films. So AddKan PPA masterbatches help in increasing the process ability of plastics like Pipes, Tubes, and Polyethylene films. It also helps in increasing the throughput rates along with improvement quality.

The most common and widely used processing aids are Fluro elastomer based. These additives along with sufficient quantity of Antioxidants allows smoother processing even at higher shear rates. You get to create a microscopically dispersed zone using this material and right within the polymer carrier.

This smooth interface created by PPA results in better flow through the die and prevents surface imperfections such as shark skin or flow marks, especially in high-speed film lines.

The addition of PPA creates a thin layer of film between the metal parts and the molten material . It thus reduces the back pressure inside the extruder. Higher addition level of PPA masterbatch is recommended in the starting of the process which will clear most of the burned particles inside the extruder and stabilize the process. PPA dosage can be then reduced to 0.5-1% levels for smooth processing. Be sure to maintain a smaller addition throughout the entire extrusion run.

AddKan PPA masterbatches allows higher throughputs even at lower temperatures thereby maintaining mechanical properties and surface gloss. Continuous use of POLYMER PROCESSING AID MASTERBATCHES can give long term benefits like lower wastage, low rejections and reduced barrel wear.

Our solutions also work effectively in combination with other performance additives like UV stabilizers for polymers and polyester masterbatches that help manufacturers achieve durable and visually appealing end products.

We welcome you to please speak to our Marketing representatives for your specific requirements. We will be more than happy to cater to your needs.

Can masterbatches be customised for specific polymer applications?

Yes, masterbatches can be tailored to match specific polymer types (like PE, PP, PET, etc.) and product requirements. This includes customized colors, functional additives, and compliance with industry standards or certifications.

Contact Us