In industries where plastics are widely used, managing static electricity is a crucial concern. From packaging sensitive electronics to producing automotive parts, even small electrostatic discharges can cause costly failures, safety hazards, or product defects. To tackle these challenges, manufacturers often rely on specialized masterbatches, particularly conductive and anti-static types. Whereas the two are used to manage static charges, they vary in functionality, degree of protection offered, and their uses. Let us explore the difference between the two.

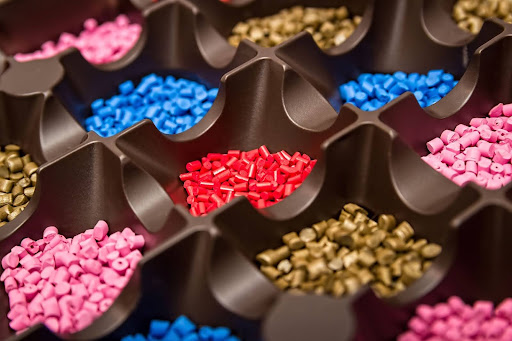

A conductive masterbatch is formulated to impart electrical conductivity to the plastic material. It includes electrically conductive fillers like carbon black, carbon nanotubes, or metallic particles, which provide paths for the free flow of electrical charges through the plastic matrix. This avoids the accumulation of static charges by permitting a constant flow of electricity.

The outcome is a material that not only withstands static—it actually carries electricity. Conductive plastics are generally utilized in applications where a greater degree of electrostatic protection is required, including electronic packaging, automotive fuel systems, and safety gear.

An anti-static masterbatch operates differently. Rather than making the plastic conductive, it minimizes the ability of the surface to collect static charges. This is done by using additives that either absorb ambient moisture or change the surface resistance of the material.

The impact is short-term and usually relies on environmental conditions such as humidity. Anti-static solutions find extensive applications in packaging films, crops, and domestic items, where it is enough to reduce static attraction to dust or avoid minor discharges.

Though both are used to control static, the differences between them are in performance, shelf life, and end-use application.

Applications that need rigorous control of electrostatic discharge (ESD) depend significantly on conductive masterbatch. Typical uses include:

Anti-static applications are prevalent in consumer and packaging applications. Some of these include:

In choosing between the two, the decision is mostly based on how much static control is needed. In situations involving high-risk environments where static discharge is harmful to electronics or can trigger flammable substances, conductive solutions are not an option. In less critical applications and if your priority is preventing dust attraction or eliminating low-level shocks, anti-static masterbatch is a more budget-friendly and efficient option.

As industries shift towards more sophisticated applications, high-performance static control materials are becoming increasingly sought after. Technological advancements in conductive fillers, including graphene and carbon nanotubes, are enhancing the cost-to-performance ratio. Meanwhile, green anti-static additives are being created to address sustainability objectives without compromising effectiveness.

Both anti-static and conductive masterbatches are pivotal in controlling static electricity in plastics. Their primary distinction is in terms of functionality, permanently securing protection through the dissipation of electrical charges, as opposed to temporary relief through the suppression of surface build-up of static. The appropriate selection hinges on the final-use application, risk level, and cost factors.

For industries requiring dependable, high-performance products, Kandui Industries provides state-of-the-art formulation that ensures consistency of performance across a wide range of applications, safe, efficient, and long-lasting.

Expert content creator passionate about sharing insights and knowledge through engaging storytelling.

View all posts